Global Aircraft Interior Fasteners Market: Highlights

Aircraft fasteners are used to assemble and hold various parts of an aircraft together. They play a vital role in an aircraft and are amongst the most essential hardware components. A wide variety of fasteners are used in the interior of an aircraft, such as bolts, screws, nuts, rivets, potted-inserts, clamps, and flanged spacers. They are used not only to join different parts of aircraft together like aircraft structure to the skin, but are also used to install and to affix components, such as seats, stowage bins, and panels to the aircraft body. Fasteners have a very large share in hardware components used in an aircraft, as about 45-50% of the components used in an aircraft are fasteners. For instance; Airbus’ A380 aircraft has six million components out of which more than three million are fasteners.

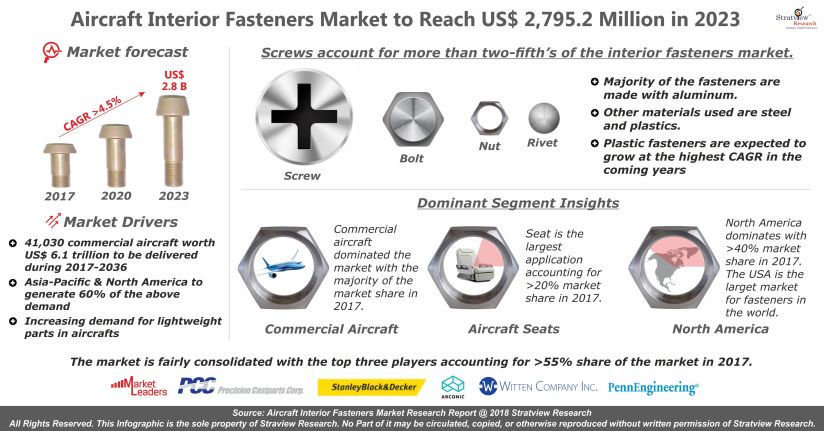

The global aircraft interior fasteners market is likely to grow at a healthy rate over the next five years to reach US$ 2,795.2 million in 2023. The major driving factor for the aircraft interior fasteners market is an incessant increase in air passenger traffic all around the world, which is triggering an increasing production rates of key programs, such as B737, A320 family, B787, and A350XWB; market entry of new players, such as COMAC and Irkut; introduction of variants of existing best-selling aircraft programs, such as B737 max, A320neo, and B777x; and increasing aircraft fleet size. All these factors are likely to contribute to a sustainable growth platform for the aircraft interior fasteners market.

The aircraft industry has efficaciously been ushering into a new era with a meticulous investment in advanced components that can address the changing business requirements in the most effective manner. All the major OEMs have vigorously been incorporating composite components in their most-renowned aircraft models with the purpose to improve the overall fuel efficiency of aircraft. Such shift from traditional metals to advanced lightweight composites is also recorded at the fasteners level as the industry stakeholders are betting on plastic fasteners, owing to its lightweight and high strength-to-weight ratio.

Fasteners for aircraft interiors are made using a wide array of materials, such as aluminum, steel, plastics, and alloys. Aluminum fasteners are the most preferred choice because of their numerous advantages, such as higher specific strength compared to steel, lightweight, and excellent corrosion and heat resistance. Plastic fasteners are steadily penetrating the aircraft interior fasteners market, as they have the advantages of being lightweight at a considerable strength against their metallic counterparts.

Aircraft fasteners are broadly categorized as male and female fasteners. Screw, bolts, rivets, and studs are part of male fasteners, whereas nut and inserts are the major types of female fasteners. Based on the fastener type, the aircraft interior fastener market is dominated by screws. The interior section of an aircraft does not require permanent joints, such as riveting, owing to the fact that airliners refurbish the entire interiors periodically.

Global aircraft interior fasteners market – Insights by aircraft type

The global aircraft interior fasteners market is segmented based on the aircraft type as Commercial Aircraft, Regional Aircraft, General Aviation, and Military Aircraft. Commercial aircraft is expected to remain the growth engine of the market during the forecast period of 2018 to 2023. Boeing and Airbus are increasing the production rates of their best-selling commercial aircraft programs in order to meet a huge pile of order backlogs. Also, COMAC and Irkut are entering the commercial aircraft industry with their C919 and MC-21 aircraft programs. Boeing anticipated that there would be total deliveries of 41,030 commercial aircraft worth US$ 6.1 trillion in the global marketplace during 2017-2036. This factor will create a sustainable demand for fasteners for commercial aircraft interiors globally in the foreseeable future.

Global aircraft interior fasteners market – Insights by Application type

On the basis of the application type, the market is segmented as Seats, Galleys, Ducts, Stowage Bins, Lavatories, Floor Panels, Sidewall Panels, Door & Windows, and Others. Seating is expected to remain the dominant application of fasteners in aircraft interiors, driven by a large number of seats per aircraft and a gradual inclination of airliners towards economy class and premium economy seats by shying away from first class seats.

Global aircraft interior fasteners market – Insights by Region

In terms of region, North America is expected to remain the largest aircraft interior fasteners market during the forecast period. The region is the manufacturing capital of the aerospace industry with presence of many large- and small-sized tier players and fastener manufacturers. Furthermore, stricter emission norms have led to a faster adoption of lighter aerospace grade fasteners in the region. The USA is not only the largest market in the region, but is also the largest market in the world.

Asia-Pacific is likely to depict the highest growth during the forecast period with China, Japan, and India being the key sources of growth. Substantial growth in air passenger and freight traffic in China and India are compelling aircraft manufacturers and tier players to open their manufacturing plants in the region. Also, both countries are incessantly increasing their defense budget with the purpose to acquire the latest military aircraft to solidify their defense capabilities. This, in turn, will create a healthy demand for fasteners in these countries in the coming years. The involvement of Japanese conglomerates to become the risk-sharing partners in the next-generation commercial aircraft and upcoming indigenous regional aircraft (Mitsubishi MRJ) will further boost the demand for fasteners in aircraft interiors in the region.

The supply chain of this market comprises raw material suppliers, aircraft interior fastener manufacturers, distributors, tier players, aircraft OEMs, MRO companies, and airlines. Key raw material suppliers for aircraft interior fasteners are Alcoa, Cytec Engineered Materials (Solvay), and Nucor Corporation; whereas some of the major tier players are Zodiac Aerospace, Rockwell Collins, and Gill Corporation.

Major aircraft interior fastener manufacturers are Precision Castparts Corp., Arconic Fastening Systems, Lisi Aerospace, Stanley Black & Decker, Inc., and Penn Engineering. Development of lightweight fasteners and forming strategic alliances with the aircraft OEMs and tier players are the key strategies adopted by the major fastener manufacturers to gain a competitive edge in the market.

Report link- https://www.stratviewresearch.com/343/Aircraft-Interior-Fasteners-Market.html

For more information, contact

Stratview Research

Email: sales@stratviewresearch.com

Direct: +1-313-307-4176